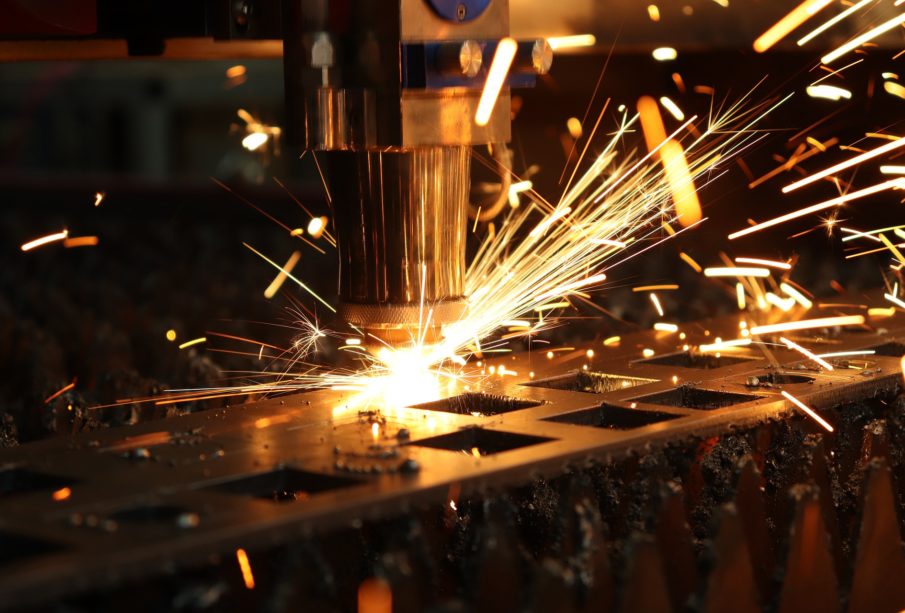

Laser Cutting: Five Advantages

Of all the processes engaged in by American industry, cutting is by far the most common. Materials even preassembled materials often need cutting prior to use. Throughout the ages, industries have used a wide variety of cutting tools to accomplish their purposes. These include shears, saws, and more, but most recently, laser cutting has emerged as the best, most efficient and cost effective yet developed.

Over the past few years, laser cutting has developed a reputation for uses far beyond any of those it was originally developed for. In fact, most experts agree that the reaches of laser cutting have yet to be truly explored. If you doubt that, read their reviews. You will become a believer. In the meantime, check out some of the advantages of using laser cutting.

Cuts Nearly All Materials

Materials that lasers can’t cut are few and far between. Lasers can cut everything from aluminum to titanium, and practically everything in between. How strong and hard a material is having no bearing on the ability lasers have to cut it. Lasers cut by using an ultra-focused beam of light to vaporize whatever the material is.

Extreme Precision

Precision. Everybody wants it but, unfortunately, practically no one can achieve the level of it they desire. Until lasers. Lasers allow users to cut materials to a degree that cannot be done practically by other methods. This benefits not only the ability for a user to cut, but to even etch to an accuracy of about 0.0005 inches. That level of accuracy is far greater than any other method now available. That’s why laser cutting is the go-to choose for a growing number of manufacturing companies. There are, of course, different types of lasers, each offering their own benefits, but as a whole, lasers are the most precise method of cutting materials yet developed.

Automation

Laser cutting can be highly automated. It is supported by different methods of control, each according to the needs of the user. They can preprogram a cutting process on a computer, then apply that program to the laser itself. The laser will then follow those program points precisely to complete the work needed.

Energy Efficiency

If there is a watchword for industry today: energy efficiency. And, there are probably few processes that are more energy efficient than laser cutting. All cutting processes require energy, but even with its use of so much concentrated energy to do its job, laser cutting is probably one of the most energy efficient methods of work available.

Smooth, High-Quality Cuts

With all the demonstrable qualities of laser cutting, what it all comes down to is the quality of the cuts made. In this regard, there is nothing like laser cutting to do the job. With practically any other process, including shears, there will be jagged cuts. It can’t be avoided. There will be jagged and sharp edges. But, with lasers, there will be no sharp or jagged surfaces. Lasers use heat, which means that edges consist of material that is melted away, and as a result, no sharp edges remain.